Thanks for contacting!

Sulzer Chemtech Ltd

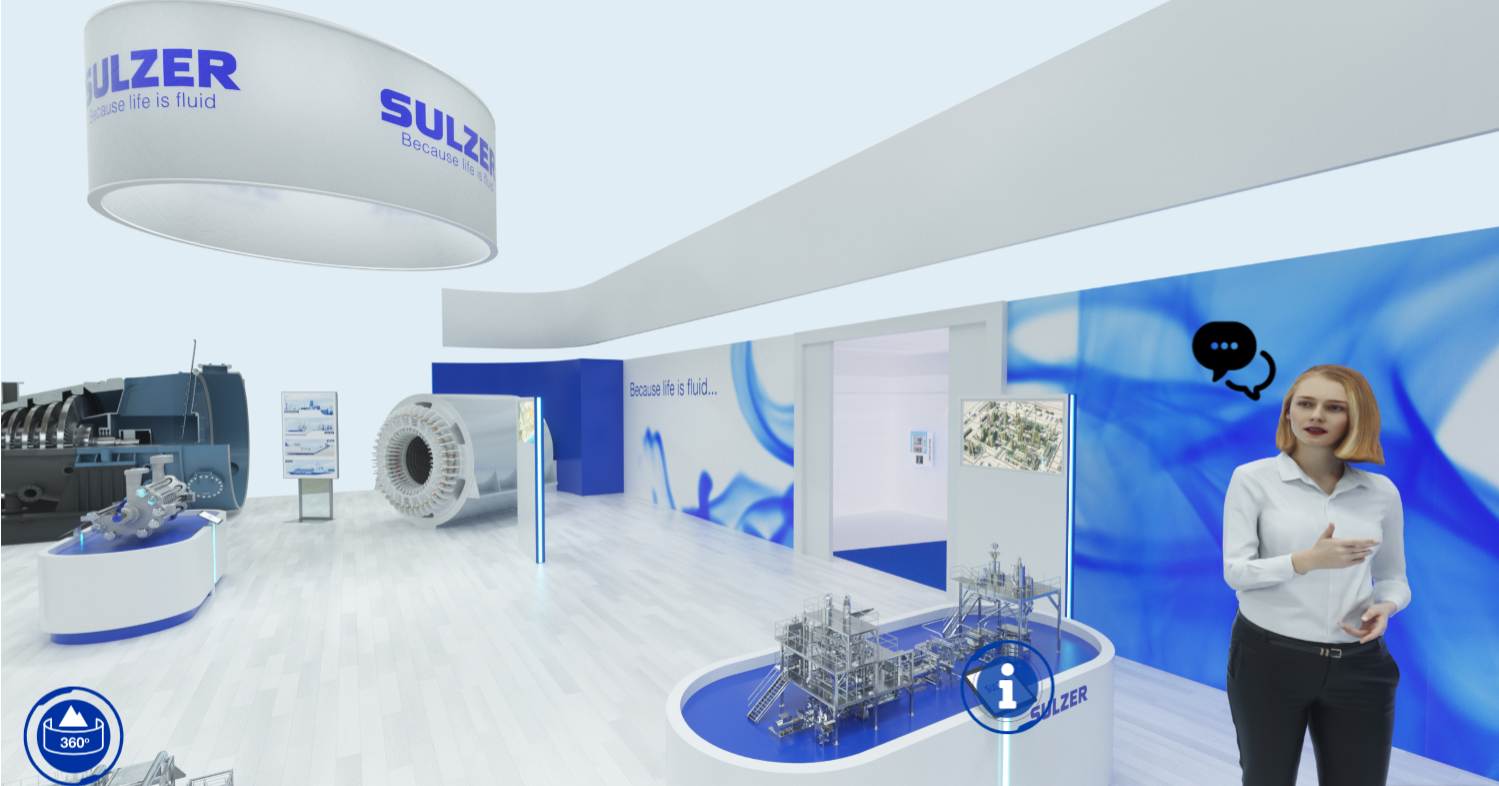

Sulzer Chemtech is a well-recognized leader in pumping, agitation and mixing solutions for the pulp and paper industry. Our product offering ranges from process components to complete separation process plants. For more than 40 years, Sulzer has been working closely with technology providers and end-users to develop separation and polymerization technologies with improved efficiency and product purity at the lowest energy consumption. We look to collaborate with Pulp and Paper industry stakeholders seeking to develop value added bioproducts from their feedstocks and side streams.

Sulzer Chemtech is a well-recognized leader in pumping, agitation and mixing solutions for the pulp and paper industry. Our product offering ranges from process components to complete separation process plants. For more than 40 years, Sulzer has been working closely with technology providers and end-users to develop separation and polymerization technologies with improved efficiency and product purity at the lowest energy consumption. We look to collaborate with Pulp and Paper industry stakeholders seeking to develop value added bioproducts from their feedstocks and side streams.